Al considerar el mecanizado de metales livianos, se eligen comúnmente el titanio y el aluminio. Estos metales están ampliamente empleados en todas las industrias debido a su relación de resistencia / peso favorable, resistencia a la corrosión y potencial de fabricación.

Los ingenieros a menudo preguntan sobre las propiedades de estos materiales en relación con sus aplicaciones específicas, como las comparaciones de peso y resistencia entre titanio y aluminio. Para ayudar en su toma de decisiones para su próximo proyecto de mecanizado, aquí hay un resumen que destaca los pros y los contras de ambos metales.

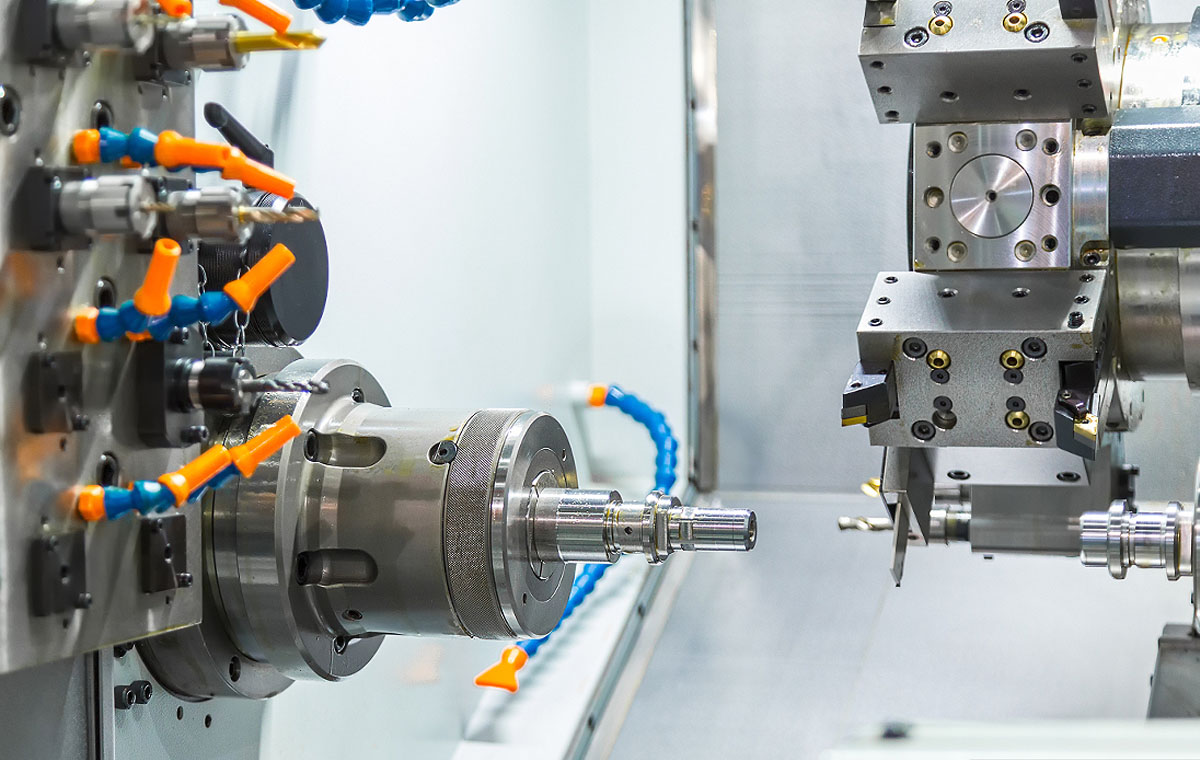

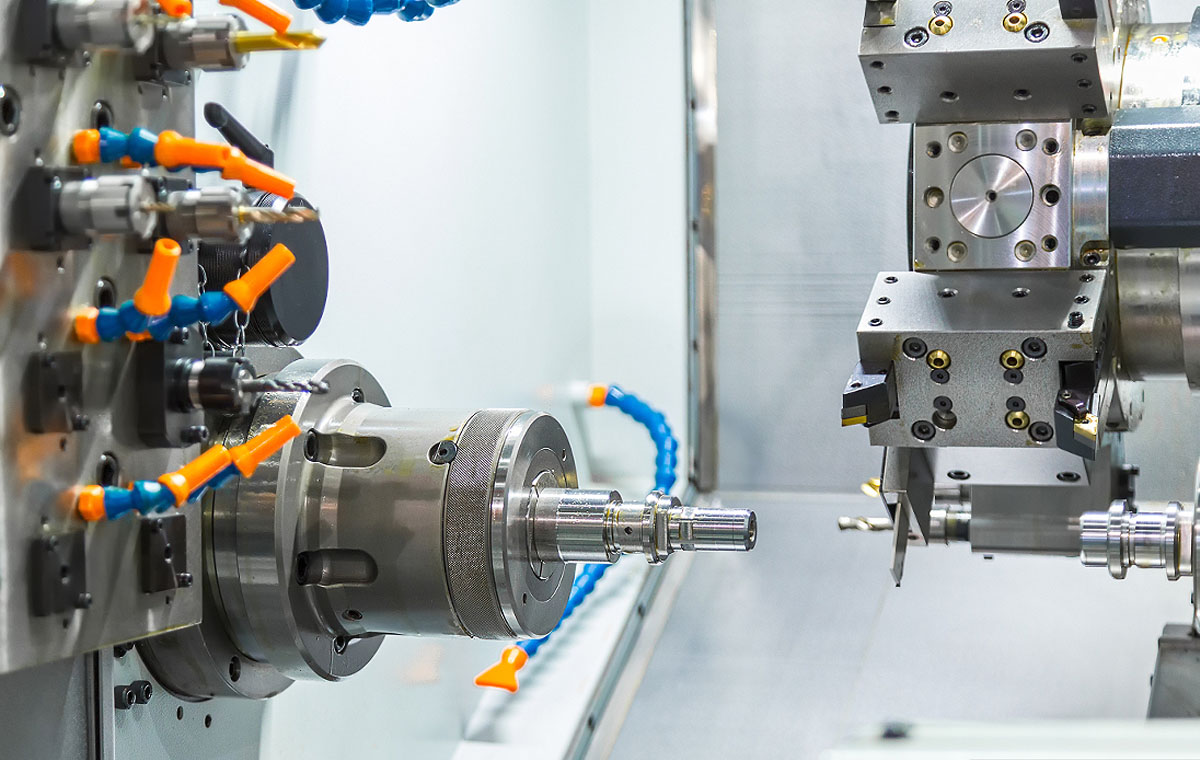

Titanio de mecanizado

El titanio es un metal versátil que se puede mecanizar para varias aplicaciones, desde implantes médicos hasta componentes de aeronaves. Es un material duradero y liviano con excelente resistencia a la corrosión, lo que lo hace adecuado para piezas que requieren resistencia y resiliencia.

El mecanizado del titanio requiere experiencia en las técnicas de corte y formación, ya que es más difícil trabajar en comparación con otros metales. Los maquinistas calificados pueden utilizar herramientas y equipos especializados para crear piezas de titanio con precisión para cualquier propósito. Los avances en tecnología han hecho que el mecanizado del titanio sea más fácil y más eficiente.

Ventajas

El titanio es conocido por su alta relación resistencia / peso, lo que lo hace ideal para aplicaciones de ingeniería como componentes aeroespaciales. También posee una resistencia a la corrosión superior, lo que lo hace adecuado para entornos marinos e industriales expuestos a productos químicos duros. Titanium encuentra usos en diversas industrias, incluida la fabricación de automóviles, la producción de equipos médicos e ingeniería química.

Desventajas

El principal inconveniente del titanio es su costo, ya que generalmente es más caro que el aluminio y otros metales. Además, la fabricación de componentes de titanio puede llevar mucho tiempo y desafiante, lo que requiere una atención cuidadosa para lograr los resultados deseados

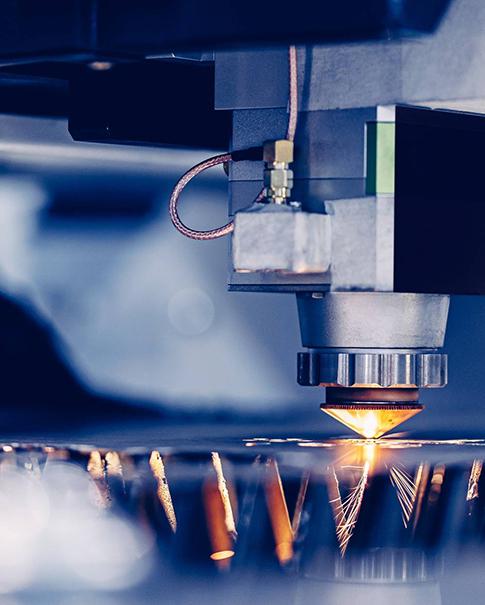

Aluminio de mecanizado

El aluminio es un material altamente versátil en mecanizado debido a su baja densidad y una relación de resistencia a peso favorable. Encuentra un uso extenso en varios proyectos de metalurgia, que van desde la construcción de maquinaria compleja hasta la producción de componentes estéticamente agradables utilizados en electrónica y diseños arquitectónicos.

La maleabilidad del aluminio facilita la forma y la talla, y sus temperaturas de procesamiento más bajas permiten modificaciones rápidas de componentes con desechos mínimos. Además, sus propiedades resistentes a la corrosión lo hacen muy deseable en muchas industrias, lo que lo convierte en una excelente opción para aplicaciones de mecanizado.

Ventajas:

A diferencia del titanio, el aluminio es significativamente más asequible, por lo que es una opción popular para los ingenieros que trabajan dentro de las limitaciones presupuestarias. Además, el aluminio ofrece una amplia gama de capacidades de tratamiento térmico, lo que permite a los fabricantes ajustar su ductilidad, dureza u otras propiedades mecánicas para cumplir con requisitos específicos.

Desventajas:

Aunque el aluminio es duradero y liviano en comparación con los metales más pesados como el acero, carece de la relación de resistencia / peso proporcionada por el titanio. Esto significa que si bien el aluminio es más barato que el titanio, la longevidad de los productos de aluminio puede ser inferior dependiendo de la aplicación

¿Cuál es mejor para mi proyecto?

Determinar qué tipo de metal es el más adecuado para un proyecto de mecanizado requiere un poco de investigación. Se debe considerar al entorno de trabajo, la complejidad del proyecto y las características deseadas al finalizar. Los proyectos de titanio tienden a requerir equipos y herramientas especializadas debido a su dureza relativa. Si un proyecto requiere detalles intrincados con una precisión excepcional, el titanio puede ser ideal debido a su fuerza robusta.

En última instancia, cada caso debe considerarse cuidadosamente teniendo en cuenta múltiples factores. Es importante sopesar las capacidades y desventajas antes de decidir sobre titanio o aluminio para su proyecto de mecanizado.

Trabajar con el equipo correcto

Safekeso es un proveedor líder de servicios de mecanizado de aluminio y titanio, conocidos por su compromiso de ofrecer componentes precisos, precisos y rentables a tiempo. Emplean equipos avanzados y técnicas innovadoras para garantizar una producción de alta calidad.

Los ingenieros calificados de Safekeso tienen una amplia experiencia en la fabricación de piezas de primer nivel utilizando varios grados de aluminio y titanio. Consistentemente ofrecen resultados confiables y pueden satisfacer diversas necesidades de mecanizado, gracias a su capacidad para lograr tolerancias más estrictas y mayores velocidades de producción.

En resumen, Safekeso es un socio confiable para proyectos de mecanizado, que ofrece experiencia, confiabilidad y eficiencia en la producción de piezas mecanizadas de aluminio y titanio.

SUSCRÍBETE A NUESTRO BOLETÍN

SUSCRÍBETE A NUESTRO BOLETÍN