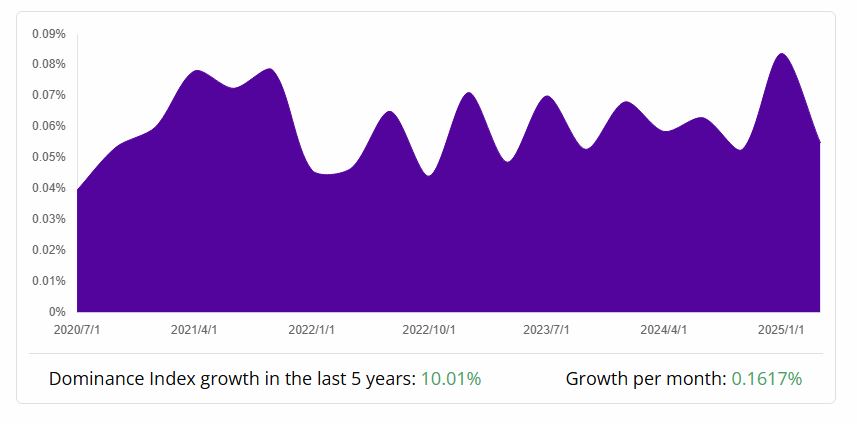

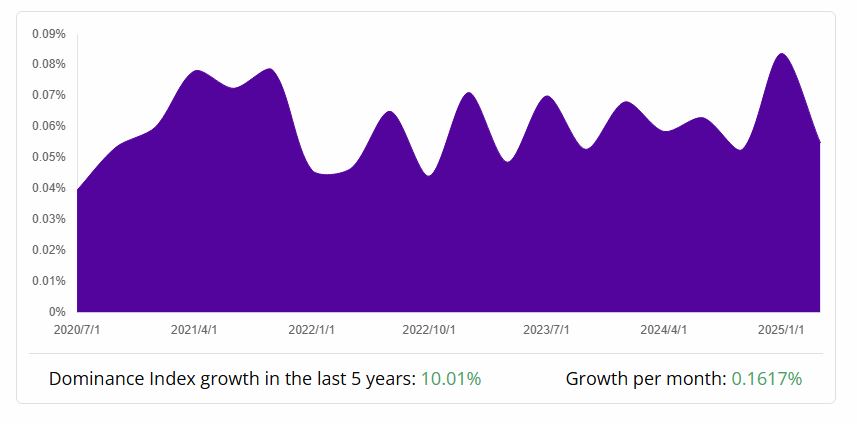

Índice de dominio temático del mecanizado CNC

La línea de tendencia del índice de dominio temático combina las distribuciones de participación de voz del mecanizado CNC a partir de tres fuentes de datos: artículos publicados, empresas fundadas y búsqueda global.

Actividades y aplicaciones clave

- Trabajo de metales de precisión: el mecanizado CNC se emplea ampliamente para cortar, tornear y fresar piezas de metal con alta precisión, lo que garantiza una calidad constante en industrias como la automotriz y la aeroespacial.

- Mecanizado multieje: la adopción de máquinas multieje mejora la capacidad de crear formas y componentes tridimensionales complejos, atendiendo a sectores que requieren procesos de producción detallados.

- Personalización y creación rápida de prototipos: el mecanizado CNC admite el enfoque de personalización masiva y la producción rápida de prototipos, lo que permite una rápida validación del concepto y mejoras iterativas del diseño.

- Integración con sistemas digitales: la creciente integración con IoT y sistemas de monitoreo basados en la nube ha agilizado los procesos de producción al permitir la gestión del rendimiento en tiempo real.

- Versatilidad del material: La tecnología permite el mecanizado de diversos materiales, incluidos metales, plásticos y compuestos, lo cual es esencial en aplicaciones que van desde la fabricación de equipos industriales hasta productos de consumo.

Tendencias emergentes y perspectivas clave

- Fabricación híbrida: la combinación de fabricación aditiva y sustractiva está surgiendo como una tendencia clave, que permite la creación de prototipos más rápidos y procesos de producción flexibles sin comprometer la calidad.

- Diagnóstico remoto e IA: la inteligencia artificial combinada con las capacidades de diagnóstico remoto está optimizando el tiempo de producción al permitir el mecanizado adaptativo y el mantenimiento predictivo.

- Mayor adopción en economías emergentes: la rápida industrialización en regiones como Asia-Pacífico está impulsando la expansión del mercado a medida que los fabricantes invierten en sistemas CNC avanzados para mantenerse competitivos.

- Soluciones y capacitación de código abierto: Las plataformas de software CNC de código abierto y los entornos de capacitación de realidad virtual están contribuyendo a la reducción de costos y a mejorar los niveles de habilidades entre los operadores.

Tecnologías y metodologías

- Centros de mecanizado multieje: La evolución de los centros de mecanizado multieje, que combinan operaciones de 3, 4 y 5 ejes en una sola línea de producción, está mejorando la precisión y reduciendo los tiempos de ciclo.

- Controladores CNC controlados por IA: los controladores avanzados que utilizan inteligencia artificial optimizan las trayectorias de las herramientas y los parámetros de corte en tiempo real para mejorar la eficiencia.

- Monitoreo basado en la nube: Las soluciones de monitoreo remoto integradas con máquinas CNC brindan una supervisión continua del rendimiento de la máquina, lo que reduce el tiempo de inactividad.

- Herramientas y materiales de corte avanzados: Se están desarrollando nuevas geometrías de herramientas de corte y técnicas de procesamiento de materiales para satisfacer las demandas de mecanizado de materiales alternativos y compuestos.

- Integración de sensores: Se están implementando sensores inteligentes para proporcionar información en tiempo real sobre las métricas de rendimiento de la máquina, como la temperatura y la vibración, lo que respalda tiempos de respuesta más rápidos y mantenimiento preventivo.

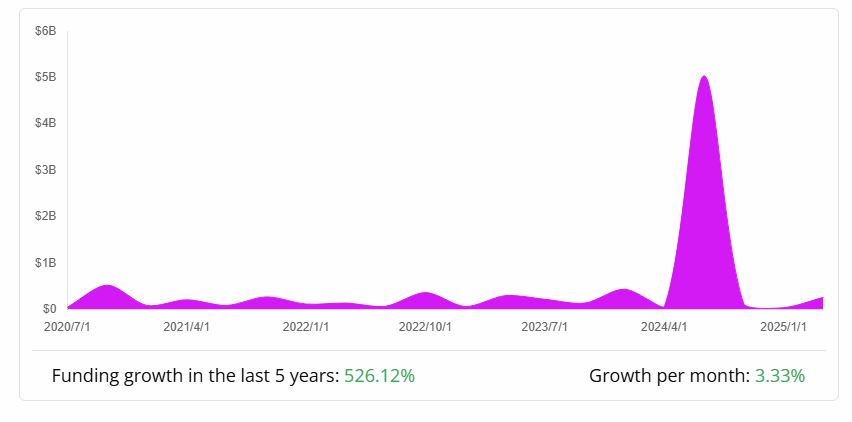

Financiación para mecanizado CNC

Un total de 1.500 empresas de mecanizado CNC han recibido financiación.

En total, las empresas de mecanizado CNC han recaudado 5.100 millones de dólares.

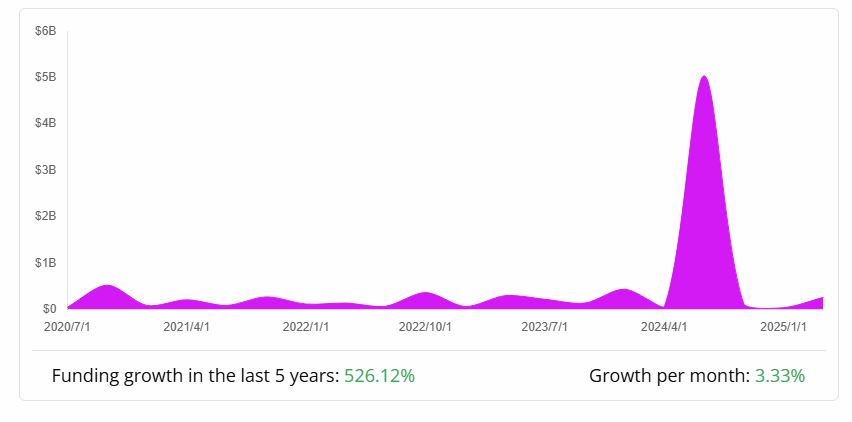

Las empresas del sector del mecanizado CNC han conseguido capital en 1.700 rondas de financiación.El gráfico muestra la tendencia de financiación de las empresas de mecanizado CNC durante los últimos 5 años.

Resumen ejecutivo

El mecanizado CNC es un pilar fundamental de la fabricación moderna, ofreciendo la precisión y eficiencia que exigen industrias de alto valor como la aeroespacial, la automotriz y la producción industrial. Las actividades clave abarcan operaciones multieje avanzadas y la integración de sistemas digitales para mejorar la calidad y reducir los desperdicios. Las tendencias emergentes, como la fabricación híbrida y la optimización impulsada por IA, prometen perfeccionar aún más estos procesos, a la vez que amplían las oportunidades de mercado. Las tecnologías y metodologías innovadoras siguen moldeando el mercado, impulsando aplicaciones en diversos sectores. Las inversiones estratégicas, tanto de empresas consolidadas como de startups ágiles en segmentos menos concurridos, destacan una industria centrada en la mejora continua y la capacidad de respuesta a las necesidades del cliente.

Buscamos colaborar con expertos de la industria para ofrecer información práctica sobre tendencias y tecnología. ¿Te interesa? ¡Contáctanos!

SUSCRÍBETE A NUESTRO BOLETÍN

SUSCRÍBETE A NUESTRO BOLETÍN